PRODUCTION

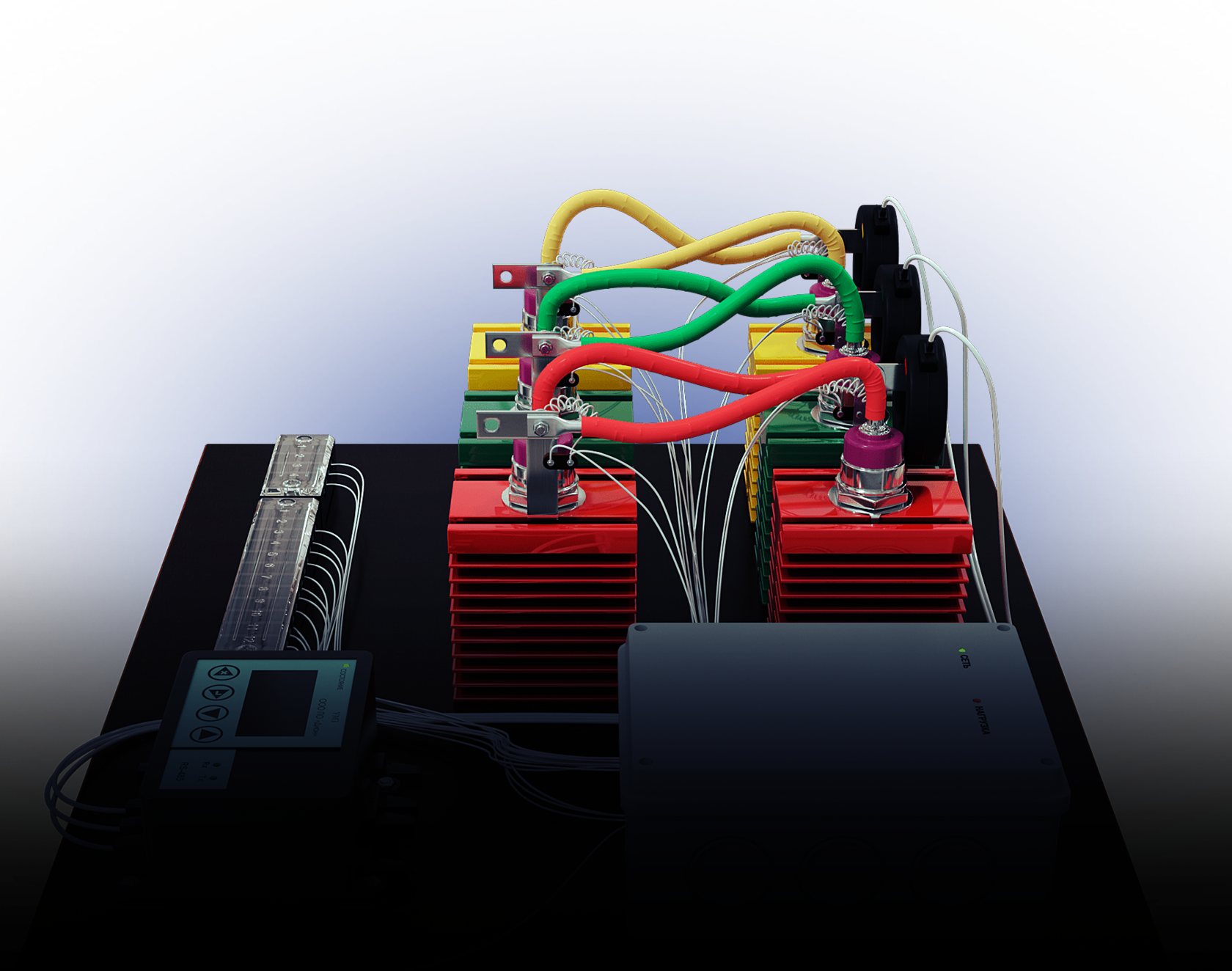

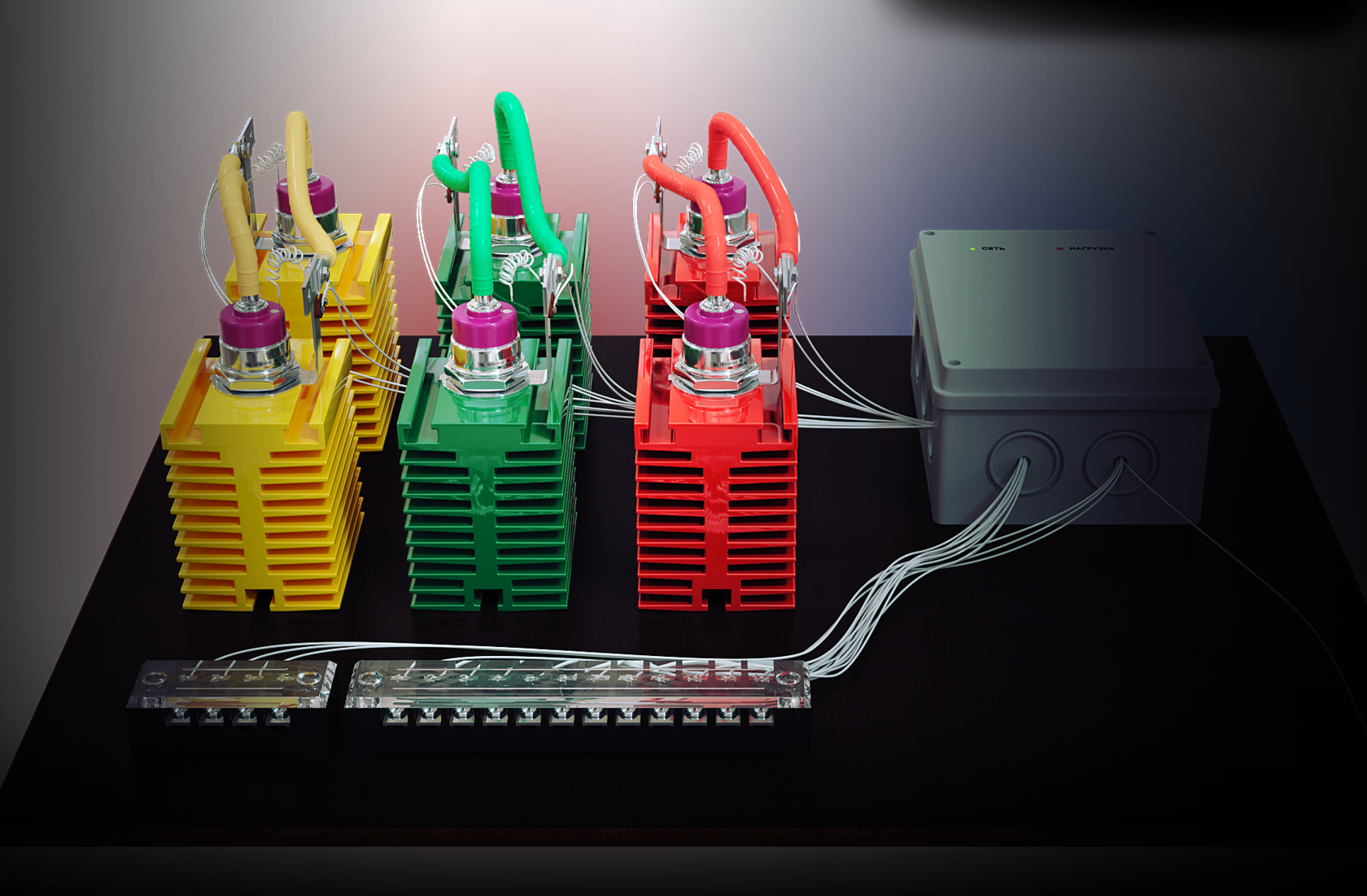

THYRISTOR CONTACTORS

Quality protection for your electrical equipment to prevent accidents

info@i-tehnology.ru

much more economical

ELECTRICITY CONSUMPTION IS LESS THAN ELECTRONIC MECHANICAL CONTACTORS

MINIMUM 100,000 HOURS

THYRISTOR LIFE AT CONTINUOUS OPERATION

150 TIMES LESS

TIME TO TURN ON OFF TC THAN EL. MECHANICAL CONTACTORS

PATENT TECHNOLOGY

Patent No. 2139626 for a system for controlling and protecting an electric drive on asynchronous electric motors

On March 18, 1998, our company received a patent

on a system for controlling asynchronous electric motors.

Certificates:

Certificate

Protocol

Protocol

Technical description

Table of overall dimensions and weight of products

ПОЛУЧИТЬ РАСЧЕТ СТОИМОСТИ

GET A PRODUCTION COST FOR YOUR ENTERPRISE

We will contact you, clarify the details and select the appropriate equipment

By clicking on the button, you consent to the processing of your personal data.

THYRISTOR CONTACTORS

DETAILED SPECIFICATIONS

10 000А

Thyristor contactors

manufactured up to 10 000A

2 YEARS

Warranty period for thyristor contactors

OVER 20 YEARS

PRODUCT LIFE

Manufactured products for 20 years have established themselves as the most reliable and stable. The service life of the product is more than 20 years, while electromechanical (KT, KVT, etc.), vacuum and oil require replacement not only of the contacts, but also of the contactors themselves. Thyristor contactors do not require constant maintenance, repair and replacement.

Saving money

Savings are made up of three factors: no labor costs for maintenance, no inductor, prevents equipment downtime.

TC

prevents

Short circuit

Phase failure of a 3-phase AC network

Voltage unbalance

Motor overheating

Jamming of the motor rotor

TC

peculiarities

TC works without shutting down,

at voltage drop up to 40%

No noise during operation

TC solves problems

Incorrect starting and braking processes

Long technological overloads

STAGES OF WORK

1. Application

form

You leave an application on our website

2. Filling out the questionnaire

According to the questionnaire, we prepare a commercial offer

3. Conclusion of an agreement

We conclude a contract with an indication of the terms and cost

4. Making an advance payment

The contract prescribes the amount of prepayment for the start of production

5. Launch into production

Terms of production of thyristor contactors from 14 days

*It is also possible to prepare products from stock

6. Delivery to the client

Delivery in a convenient way to your company

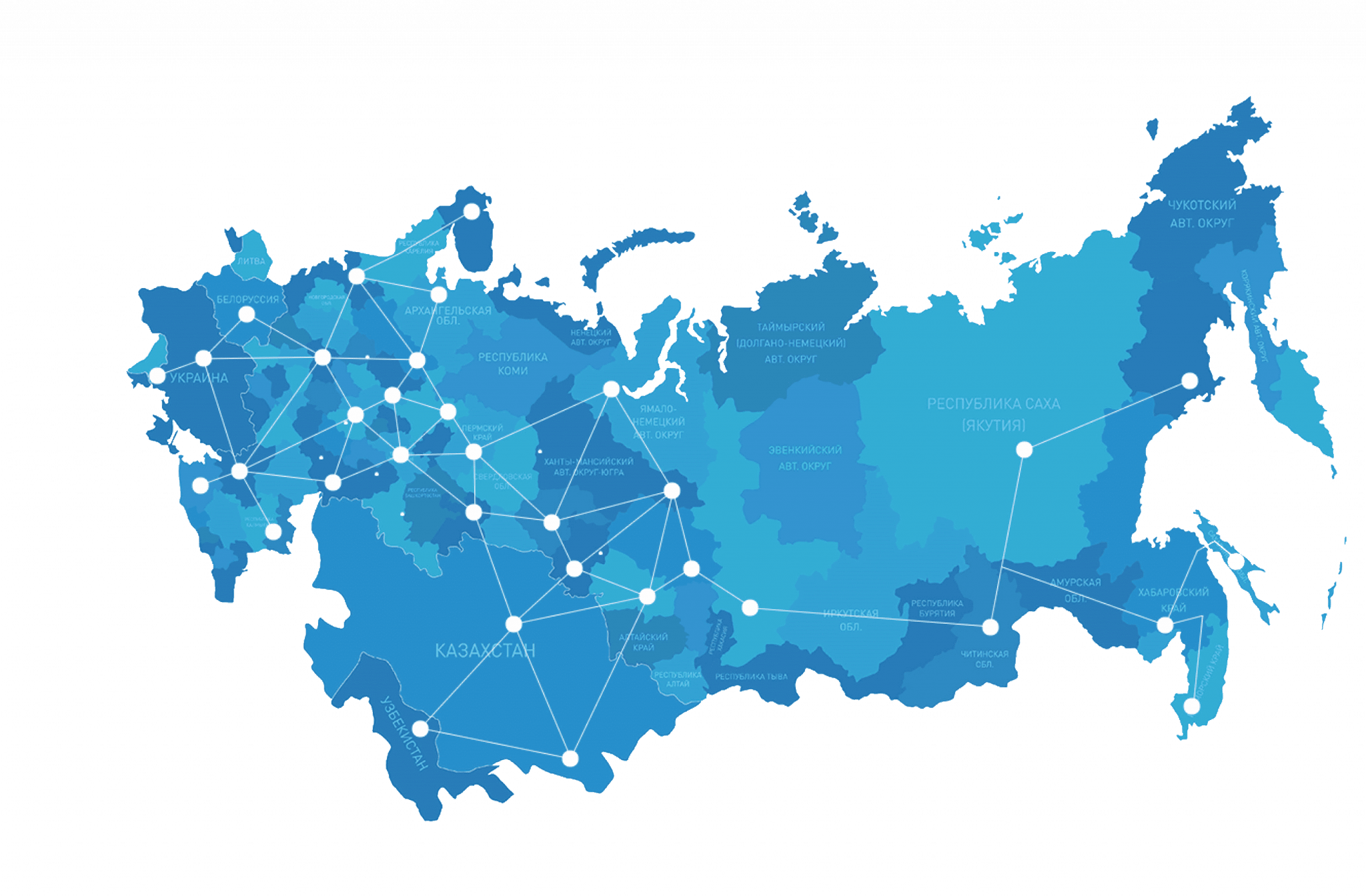

GEOGRAPHY OF SUPPLY

Regions of Russia and CIS countries with which we work

OUR CLIENTS

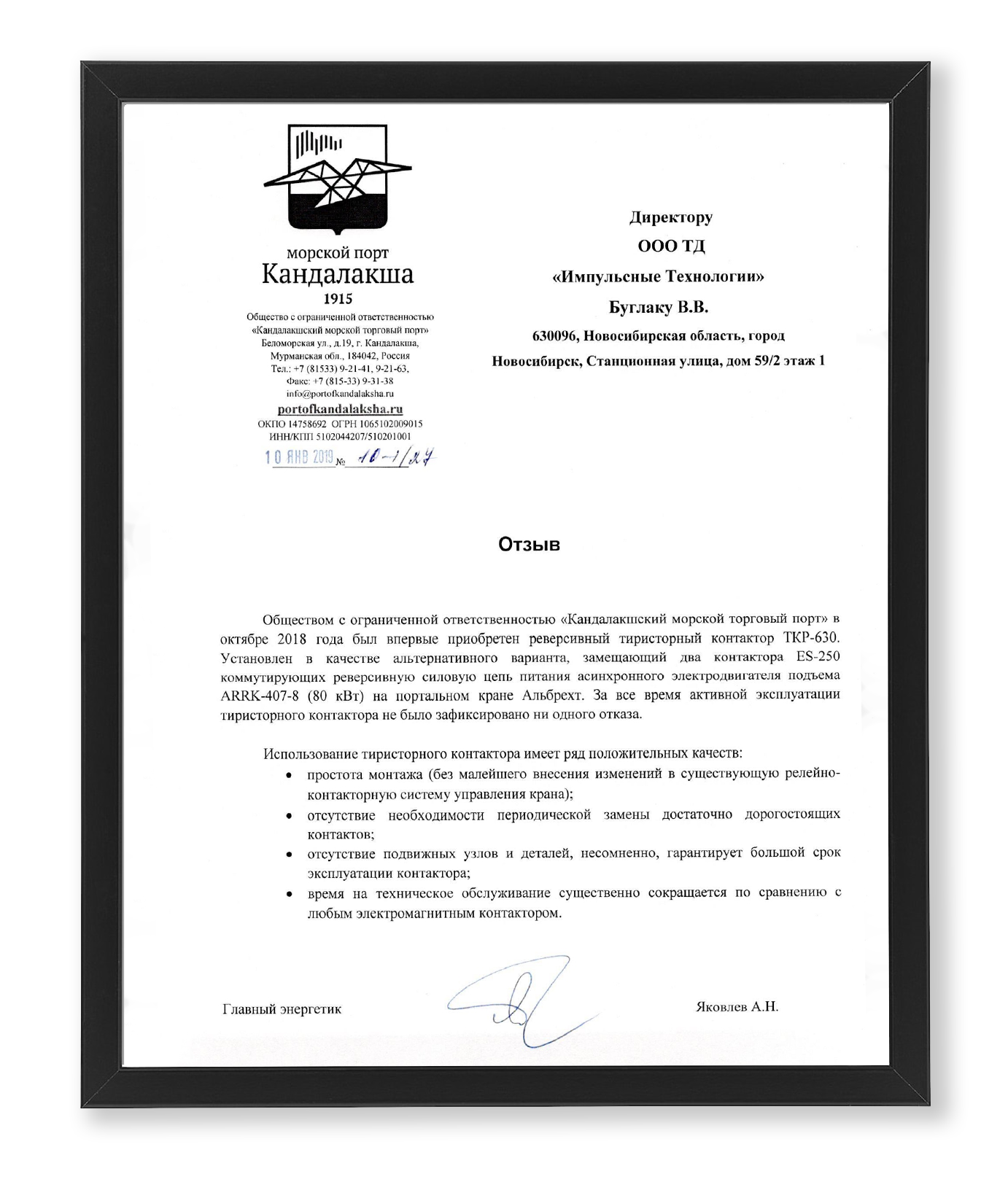

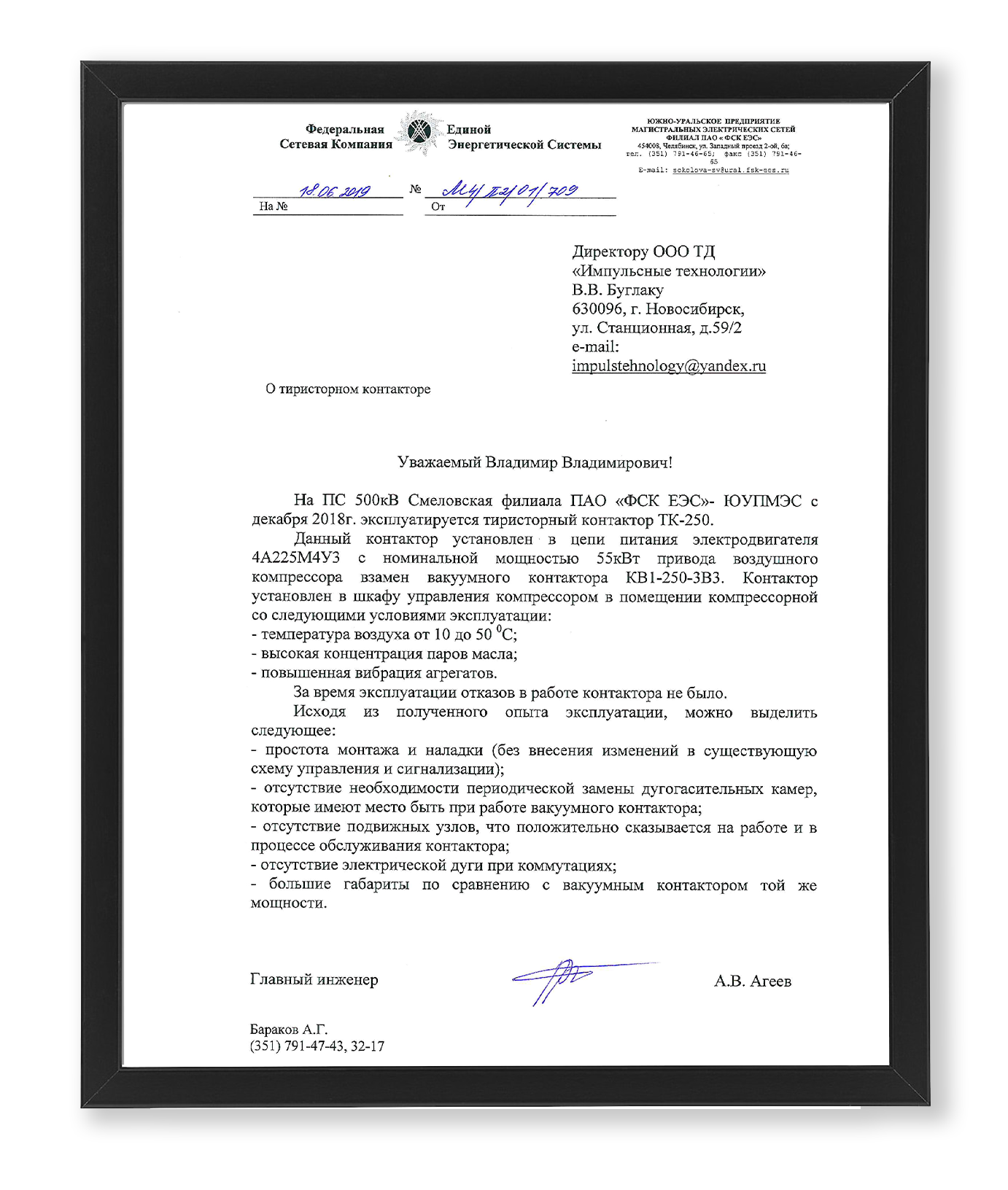

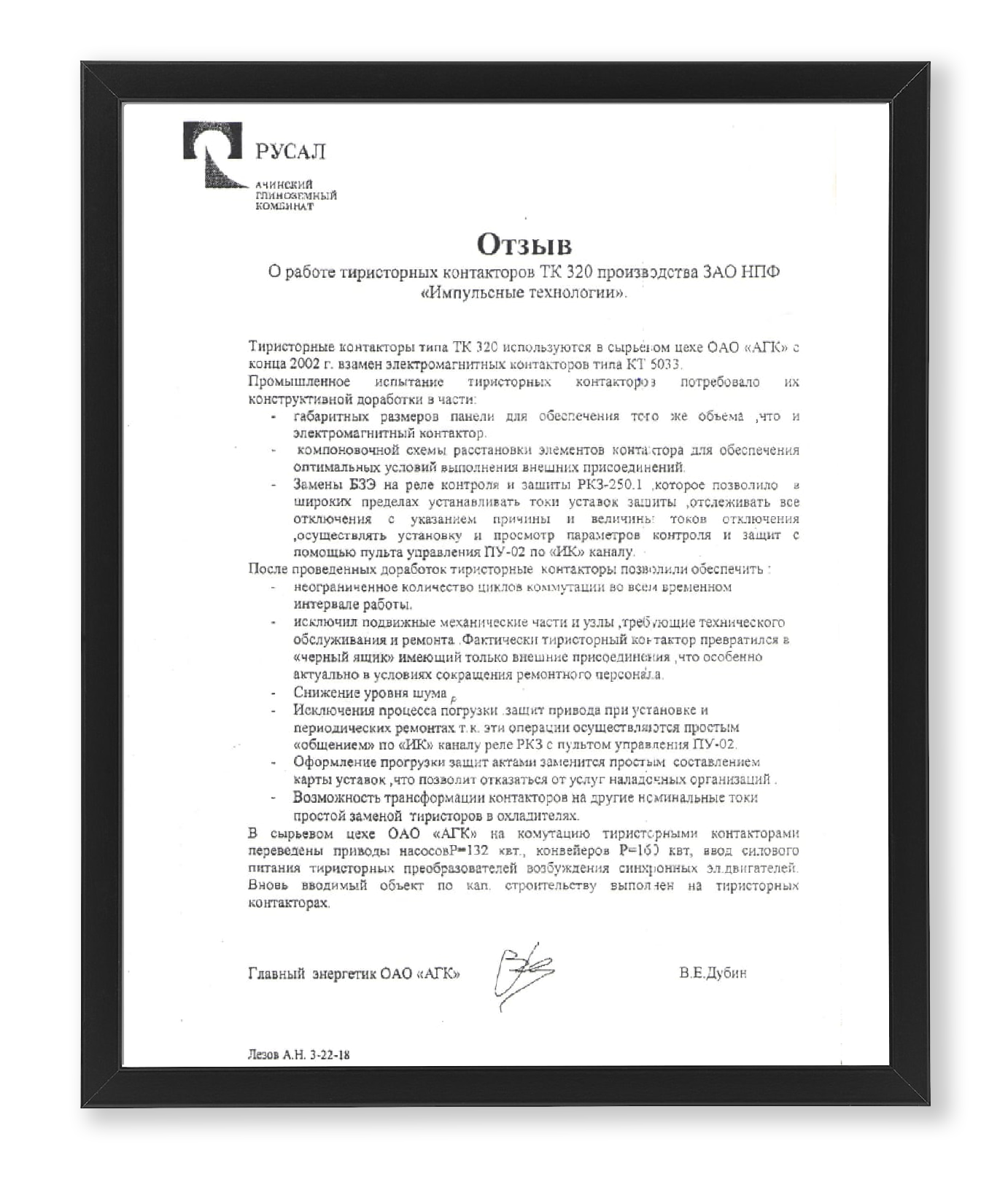

REVIEWS

IMPORT SUBSTITUTION

ALL ACCESSORIES ON THE RUSSIAN THYRISTOR CONTACTOR

ПОЛУЧИТЬ РАСЧЕТ СТОИМОСТИ

GET A PRODUCTION COST FOR YOUR ENTERPRISE

We will contact you, clarify the details and select the appropriate equipment

By clicking on the button, you consent to the processing of your personal data.

PRODUCTION

SWITCHING EQUIPMENT

SWITCHING EQUIPMENT

Russia, Novosibirsk region,

Novosibirsk city,

st. Trolleynaya, 87/1k1

Novosibirsk city,

st. Trolleynaya, 87/1k1

info@i-tehnology.ru

© 2022 Impulse technology

cement plants

Supply and exhaust ventilation

Very often in dirty industries, dust clogs mechanical contacts (poor contact, sticking). The use of a contactor with a closed control board prevents the failure of electrical equipment and downtime of production in general.

Сonveyor belts

Screw conveyors

In industries where a screw conveyor is used, dust clogs mechanical contacts (poor contact, sticking). The use of a thyristor contactor with a closed control board prevents equipment failure.

Сrushers

TK-200A for Norilsk Nickel for ore crushers

Long-term use of the equipment caused the failure of mechanical contactors due to the peculiarities of the technological process of grinding ore. The supplied thyristor contactors have been operating for more than 10 years.

Long-term use of the equipment caused the failure of mechanical contactors due to the peculiarities of the technological process of grinding ore. The supplied thyristor contactors have been operating for more than 10 years.

Oil and gas industry

Pump stations for pumping oil and gas

A prototype TK-250A for a 0.4 kW pumping station for the Ufa Oil Refinery

The system control of pumps during oil pumping is connected with the system control via a computer. The response time of the KT contactor is 0.5 s, the response time of the thyristor contactor and the computer is 0.01 s. In case of emergency shutdowns, the CT does not have time to turn off the pressure of the oil column in time; there is no failure with the thyristor contactor (TC). In winter, condensate accumulated from the heating of mechanical contacts, which led to the failure of the CT, this does not happen with the TC, since there is no mechanical contact.

The system control of pumps during oil pumping is connected with the system control via a computer. The response time of the KT contactor is 0.5 s, the response time of the thyristor contactor and the computer is 0.01 s. In case of emergency shutdowns, the CT does not have time to turn off the pressure of the oil column in time; there is no failure with the thyristor contactor (TC). In winter, condensate accumulated from the heating of mechanical contacts, which led to the failure of the CT, this does not happen with the TC, since there is no mechanical contact.

Metallurgy

Furnaces

Modernization of Kemerovokhimmash furnaces

Maintaining a temperature regime with a tolerance of 1 degree requires a high frequency of switching on and off, which leads to an early failure of the electromechanical contactor due to sticking of the contacts. The thyristor contactor works on the principle of a contactless key, therefore it has an almost unlimited on / off frequency, which eliminates the problem.

Maintaining a temperature regime with a tolerance of 1 degree requires a high frequency of switching on and off, which leads to an early failure of the electromechanical contactor due to sticking of the contacts. The thyristor contactor works on the principle of a contactless key, therefore it has an almost unlimited on / off frequency, which eliminates the problem.

Induction Furnaces

Roller tables

TKR-160A for Norilsk Nickel

The frequency of switching on and off leads to premature wear of the mechanical parts of the CT. The use of a thyristor contactor prevents equipment failure, and the useful life is at least 2 years (on average, 7 years)

The frequency of switching on and off leads to premature wear of the mechanical parts of the CT. The use of a thyristor contactor prevents equipment failure, and the useful life is at least 2 years (on average, 7 years)

Tube rolling electric drives

Simultaneous exposure to dust, dirt and temperature leads to wear of the mechanical parts of the CT. In thyristor contactors (TC), this is excluded, since the temperature operating modes of the TC are from -60 ° С to + 120 ° С

Modernization of Kemerovokhimmash furnaces

Maintaining a temperature regime with a tolerance of 1 degree requires a high frequency of switching on and off, which leads to an early failure of the electromechanical contactor due to sticking of the contacts. The thyristor contactor works on the principle of a contactless key, therefore it has an almost unlimited on / off frequency, which eliminates the problem.

Maintaining a temperature regime with a tolerance of 1 degree requires a high frequency of switching on and off, which leads to an early failure of the electromechanical contactor due to sticking of the contacts. The thyristor contactor works on the principle of a contactless key, therefore it has an almost unlimited on / off frequency, which eliminates the problem.

mining industry

Transporters

The control board of the TC is enclosed in an IP65 housing, which allows the use of the TC at dusty sites.

Induction Furnaces

Roller tables

TP-25A for starting ventilation on Siberian anthracite

The activation of the ventilation system at the processing plant took place through a conventional electromagnetic starter. Coal dust caused the breakage of the starter from time to time. The thyristor starter completely solves this problem and serves with a guarantee of more than 10 years.

The activation of the ventilation system at the processing plant took place through a conventional electromagnetic starter. Coal dust caused the breakage of the starter from time to time. The thyristor starter completely solves this problem and serves with a guarantee of more than 10 years.

Tube rolling electric drives

TK-200A for PJSC Norilsk Nickel

The 45KW pump was operated in an aggressive environment, among the negative factors - a large amount of dirt and dust. The control board of the thyristor contactor is enclosed in a moisture- and dust-proof housing, which allows it to operate even in the most aggressive conditions.

The 45KW pump was operated in an aggressive environment, among the negative factors - a large amount of dirt and dust. The control board of the thyristor contactor is enclosed in a moisture- and dust-proof housing, which allows it to operate even in the most aggressive conditions.

TK-200A for Norilsk Nickel for ore crushers

Long-term use caused failure of mechanical contactors due to the peculiarities of the technological process of grinding ore, the thyristor contactor works with a guarantee of more than 10 years.

Long-term use caused failure of mechanical contactors due to the peculiarities of the technological process of grinding ore, the thyristor contactor works with a guarantee of more than 10 years.

Content Oriented Web

Make great presentations, longreads, and landing pages, as well as photo stories, blogs, lookbooks, and all other kinds of content oriented projects.

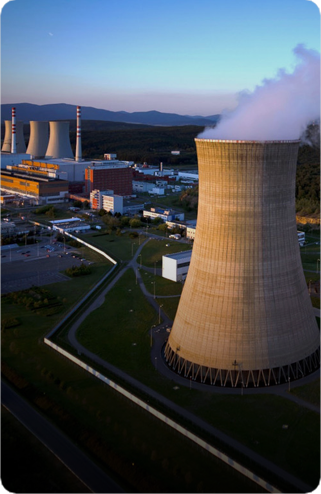

Power generation

Car pushers (reverse)

Pumps

TС-100A for Achinsk heating systems

The mechanical contactor that starts the pump does not tolerate high humidity. The solution was to install a thyristor contactor, which is protected from the negative effects of water vapor.

The mechanical contactor that starts the pump does not tolerate high humidity. The solution was to install a thyristor contactor, which is protected from the negative effects of water vapor.

Transformer substations

TK-1000A at KTPN for APS project company (under their project for Surgutneftegaz)

Frequent switching on and off leads to failure of electromechanical contactors. Thyristor contactors will reduce the cost of spare parts replacement and unscheduled work.

Frequent switching on and off leads to failure of electromechanical contactors. Thyristor contactors will reduce the cost of spare parts replacement and unscheduled work.

Frequent switching on and off of car pushers leads to failure of electromechanical contactors. Thyristor contactors will reduce the cost of spare parts replacement and railcar downtime.

Crane facilities

Gantry cranes, beam cranes

TKR-630A for the Kandalaksha sea port on the portal crane Albatros

Since coal dust is conductive, contacts close on the portal cranes, which causes failure of the CT. The solution was to install a thyristor contactor, which is protected from the negative effects of coal dust thanks to a moisture and dust tight device.

Since coal dust is conductive, contacts close on the portal cranes, which causes failure of the CT. The solution was to install a thyristor contactor, which is protected from the negative effects of coal dust thanks to a moisture and dust tight device.

mechanical engineering

Conveyors

Supply and exhaust ventilation

Prolonged use caused mechanical contactors to fail and ventilation to stop. The service life of the thyristor contactor is at least 7 years of trouble-free operation, which reduces the routine maintenance of equipment.

Pumps

TC-1000A from UMP to Altaivagon for a 75 kW engine

Prolonged use caused mechanical contactors to fail and pumps to stop. Thyristor contactor service life of at least 7 years of trouble-free operation allows reducing routine equipment maintenance

Prolonged use caused mechanical contactors to fail and pumps to stop. Thyristor contactor service life of at least 7 years of trouble-free operation allows reducing routine equipment maintenance

Frequency converter and TC instead of introductory machine for Agrospetsmash

TC is designed for a pump for an irrigation system.

TC is designed for a pump for an irrigation system.

Ferroalloy plants

Crane facilities

Supply and exhaust ventilation

Since ferroalloy dust is conductive, then in mechanical contactors to start el. the engine is inadvertently shorted, which leads to failure of ventilation.

Pumps

TCR-500A for Aktobe Ferroalloy Plant

Since ferroalloy dust is conductive, mechanical contactors for starting the electric motor inadvertently close contacts, which leads to failure of the crane facilities.

Since ferroalloy dust is conductive, mechanical contactors for starting the electric motor inadvertently close contacts, which leads to failure of the crane facilities.

TC-100A for an induction furnace for hardening products for the Litkom plant

An unlimited frequency of switching on and off leads to failure of the electromechanical contactor. The use of TC increases the service life of the furnace and reduces equipment downtime

An unlimited frequency of switching on and off leads to failure of the electromechanical contactor. The use of TC increases the service life of the furnace and reduces equipment downtime

housing and communal services

Elevator facilities (reversing contactors)

A high frequency of switching on and off leads to failure of the electromechanical contactor. The use of a thyristor contactor increases the service life and prevents unwanted failure during the operation of the elevator.

Pumps for water supply and heating

TC-100A for Achinsk heating systems

The mechanical contactor that starts the pump does not tolerate high humidity. The solution was to install a thyristor contactor, which is protected from the negative effects of water vapor.

The mechanical contactor that starts the pump does not tolerate high humidity. The solution was to install a thyristor contactor, which is protected from the negative effects of water vapor.